Since the radiant heat from your furnaces and the crucibles when pulled are going to be pretty hard on your OSB wall over time. I would recommend placing some 5/8" fire proof drywall over it. I did in my foundry but I still had the paper covering start to buckle over time. I was lucky in that a guy selling scrap aluminum stopped by with a used piece of 3/16" X 4' X 8' sheet of aluminum diamond plate and being sold at the scrap lbs price which I then placed in front of the drywall with 1" spacers between the two and a couple inches off the floor so an air flow could move the heat radiated to the plate up and away and not tranferring it to the drywall. This has stopped any more concerns of wall deterioration. Maybe some of your street signs place in like manner would do the same thing as my diamond plate has done. Just a heads up. BobHarry wrote: The OSB I picked up yesterday will be going on that back wall.

Lil Scrapper

Re: Lil Scrapper

I used to spend my time to save money but now I'm willing to spend my money to save time.

Re: Lil Scrapper

I would love to set up like that Nudge, the ceiling is kind of low with the current setup though. It still may be feasible and believe me I have given it consideration. It will be built into Foundry 2.0 for certain.

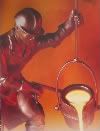

This is a rebuild of one of the two furnaces I have. This will be a #20 and the little furnace is a #10. Of course the Big Scrapper is coming soon too so that will make three.

Bob, thanks for the heads up. I had not considered any problem with heat on the wall. Will need to take the temperature when I do the first firing on the rebuild as this will be about as hot as it will ever get. I did think about the wiring and electrical conduit and heat but did not think it would be any problem.

This is a rebuild of one of the two furnaces I have. This will be a #20 and the little furnace is a #10. Of course the Big Scrapper is coming soon too so that will make three.

Bob, thanks for the heads up. I had not considered any problem with heat on the wall. Will need to take the temperature when I do the first firing on the rebuild as this will be about as hot as it will ever get. I did think about the wiring and electrical conduit and heat but did not think it would be any problem.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

The hotface is now in, took about 100 lbs of 3K* mizzou and ended up just over 1 1/4" thick on the walls and 1 1/2" thick on the top. This thing should be bullet proof. I took a few pictures and will post them later, just in because I had a call from PBC for the accounting department of CastCNC while I was up to my elbows in refractory mud and got cut off while trying to explain to them how to bill me on states where tax is charged... sheez, funny how the accounting department from a one man company has to explain this stuff to a big outfit like that.

I am hoping this is going to be set enough to put a small fire in it this evening and maybe even burn it in but I think that will have to wait until tomorrow. I have to get these wheels scrapped out before my helper comes over Monday because I dont have enough ingots for what I plan to pour next week. Also need to set up the second molding bench and would like to get the tongs made for the #20 crucible so I can use it but if it doesnt happen the #10 should have no trouble keeping up with both of us molding. Been busy as hell lately with a number of projects and have had a bumper number of orders this month so its not going to slow down any time soon.

I am hoping this is going to be set enough to put a small fire in it this evening and maybe even burn it in but I think that will have to wait until tomorrow. I have to get these wheels scrapped out before my helper comes over Monday because I dont have enough ingots for what I plan to pour next week. Also need to set up the second molding bench and would like to get the tongs made for the #20 crucible so I can use it but if it doesnt happen the #10 should have no trouble keeping up with both of us molding. Been busy as hell lately with a number of projects and have had a bumper number of orders this month so its not going to slow down any time soon.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

Harry wrote:The place I buy from HT doesnt really sell to the public. they have crews that install these materials and my guess is they buy pretty large quantities and mark it up pretty good when they sell to people like myself. Its kind of funny because I thought it was a little high but I had not purchased any for some time.

The place where I go is the same, But they dont mark it up extra for me, they came right off that price list. they did ask that next time, I Order rather then show up, and they will have it dropped shipped to me, but that will be years down the road, and I will probably just forget

Re: Lil Scrapper

Man, that thing looks like it is never going to dry, between the 6 gallons of water in it from yesterday and the water in the hotface I put in today it is like the whole thing is all water. I peeled out the sono tube and it left the face a little rough because it was still so wet but I had to get a torch in there. Left it on low with a full bottle so hoping it will draw a lot of the water out. I really need to fire this thing tomorrow, I can always smooth up the face later with super 32 if I need to but I dont think it being rough is going to hurt anything at all and that 1" plus face isnt going anywhere soon.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

Went out and checked the torch, still going and about 130* in the furnace. I have a couple boards on top propped up so it is venting well but holding some of the heat. The idea is to allow a good draft so the moisture will come out with the draft. It is firming up good now so maybe there is hope.

A rolled up piece of cardboard from a shoe box for the form cut to somewhat match the sono tube. I wasnt too worried about geting it perfect because I planned to peel the sono tube while it was still somewhat green but ended up peeling it while it was still very wet. The sono tube for the hot face form spaced at three points to hold it in place. Here the sono tube is peeled, you can see some of the wall is pretty rough. If I had more time I would have been more careful with the tuyere form so I wouldnt have to work that and left the sono tube in and let it dry slow but with it out the water can evaporate much quicker. And a shot turned the other direction. You can see the pergola we built on the deck and just to the left of it in the tree you can see the green fabric top of the gazebo on the other side of the yard. Need to take the tops off both of those for the winter soon. All the trees I planted as little sticks.

A rolled up piece of cardboard from a shoe box for the form cut to somewhat match the sono tube. I wasnt too worried about geting it perfect because I planned to peel the sono tube while it was still somewhat green but ended up peeling it while it was still very wet. The sono tube for the hot face form spaced at three points to hold it in place. Here the sono tube is peeled, you can see some of the wall is pretty rough. If I had more time I would have been more careful with the tuyere form so I wouldnt have to work that and left the sono tube in and let it dry slow but with it out the water can evaporate much quicker. And a shot turned the other direction. You can see the pergola we built on the deck and just to the left of it in the tree you can see the green fabric top of the gazebo on the other side of the yard. Need to take the tops off both of those for the winter soon. All the trees I planted as little sticks.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

Burning in now, its up to about 2K* and steaming away. For a little while I was worried about how much water and steam was coming out of this thing, definitely better to let a furnace dry more on its own but like I said I am in a rush on this now.

Been fighting the second molding bench ever closer to the foundry, man that thing must weigh four hundred pounds.

Been fighting the second molding bench ever closer to the foundry, man that thing must weigh four hundred pounds.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

After about five hours of steaming I shut it down, still had a little water coming out of this damn thing. Looks like it fired fine on the inside just fine and is ready to use, I did have the Kast-O-Lite plinth in there and it slumped over not being able to take the heat, will have to make a new plinth using the Mizzou but I dont need that right now anyhow so no big deal.

Tomorrow I will be scrapping out about 400 lns of wheels if all goes well. With the smaller bore that the furnace now has it will hold less in the bottom when tilted and also be more troublesome getting them to go in but hopefully this will be the last scrapping run in this furnace and the big scrapper will be done.

The outside of the furnace never got much about 200* which was probably 100* or more cooler than it ran before so that worked out well but I did measure the temperature of the wall behind the furnace and found a spot as warm as 135* so I will follow Bobs suggestion and put those aluminum construction signs on that wall spaced off about 3/4" for air flow.

Tomorrow I will be scrapping out about 400 lns of wheels if all goes well. With the smaller bore that the furnace now has it will hold less in the bottom when tilted and also be more troublesome getting them to go in but hopefully this will be the last scrapping run in this furnace and the big scrapper will be done.

The outside of the furnace never got much about 200* which was probably 100* or more cooler than it ran before so that worked out well but I did measure the temperature of the wall behind the furnace and found a spot as warm as 135* so I will follow Bobs suggestion and put those aluminum construction signs on that wall spaced off about 3/4" for air flow.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Lil Scrapper

Good stuff! I was supprised with the amount of water that my refractory held but as you said fire it up and let it steam for a few hours.... All was good

I like to build "Stuff" using Stuff that costs Stuff All!

Re: Lil Scrapper

I could hardly believe the instructions were correct.

Scrapped about 250 lbs of wheels and some castings that needed a do over Worked great even with the smaller bore. I think this furnace is going to work out perfectly as a #20 crucible furnace. Also plumbed in propane to the air on the siphon nozzle and got to say I sure think I like it. Will start another thread for talking about that though.

Worked great even with the smaller bore. I think this furnace is going to work out perfectly as a #20 crucible furnace. Also plumbed in propane to the air on the siphon nozzle and got to say I sure think I like it. Will start another thread for talking about that though.

Scrapped about 250 lbs of wheels and some castings that needed a do over

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller