Here is my furnace. Since I am able to do welding jobs, my furnace is mounted on a sled to get moved out of the shed. It´s build out of scrap. The big advantage now is the burner is only fixed by a screw and so can be taken out. The mouth piece, which is in the furnace (1600°C refractory) is really static. It´s sealed with refractory mud. So no bypass air anymore. The lining was partly overhauled (1260°C ceramic fiber). There are three layers in the furnace, and only the outer lining was replaced. If you ask me cheap refractory is not worth it for longer terms of use.

Also I know ceramic fiber is not the best so for my next bigger furnace ther will be a refractory hotface an a ceramic fiber back lining.

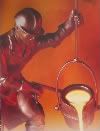

The biggest crucible is an A#6 SiC (in the picture). The furnace is quite fast now. Since using a refractory mouthpiece I never experienced problems with the 1" burner.

My Furnace (1" Hybrid Burner)

My Furnace (1" Hybrid Burner)

Last edited by _FL_ on Tue Nov 15, 2011 11:41 am, edited 1 time in total.

Re: My Furnace (1" Hybrid Burner)

Those tongs look nice, are they forged?

I agree 100% on the use of a good refractory material. My first furnace ended up just being a waste of time using the BYMC mix, I completely melted it within the first week or two.

I agree 100% on the use of a good refractory material. My first furnace ended up just being a waste of time using the BYMC mix, I completely melted it within the first week or two.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: My Furnace (1" Hybrid Burner)

what ya mean nice, thems just dang pretty, along with that is a pair of hand hammered charging tongs lying in the top right hand corner of that picture isn't it.

Damn Fine work there mr _FL_ damn fine work. they almost make me cry compaired to the ones I knocked together when I need a new set

David

Damn Fine work there mr _FL_ damn fine work. they almost make me cry compaired to the ones I knocked together when I need a new set

David

David and Charlie aka the shop monster

If life seems normal your not going fast enough" Mario Andrette

If life seems normal your not going fast enough" Mario Andrette

Re: My Furnace (1" Hybrid Burner)

Sorry for the late reply... I had an internet-blackout due to lightning strike.

Yes, the tongs are forged - but not by me. I bought them. No matter they will last a long time. Now I would be able to build some of my own. Within the short time of my BYMC career I learnt a lot of useful things (Oct. 2010). Luckily I found it just in time. AA is a bit different to me now, sort of confusing.

Got two piece of them. The charging tongs is original for fireplaces. I used one as a skimmer with some metal (fixed with wire). On the right hand side is a #10 MIFCO safety shank waiting for some action. At the moment I pour from #4 and #6 SiC crucibles with the forged tongs. Good idea to think about a pouring shank for them.

One more thing about the crucibles: If you can get them, go for the SiC ones. Last winter I fired a graphite type crucible which seems to contained some moisture. There was a lot of cracking noise and some damage. With SiC crucibles there where no such problems - no matter what temperature or moisture. They last quite long.

Yes, the tongs are forged - but not by me. I bought them. No matter they will last a long time. Now I would be able to build some of my own. Within the short time of my BYMC career I learnt a lot of useful things (Oct. 2010). Luckily I found it just in time. AA is a bit different to me now, sort of confusing.

Got two piece of them. The charging tongs is original for fireplaces. I used one as a skimmer with some metal (fixed with wire). On the right hand side is a #10 MIFCO safety shank waiting for some action. At the moment I pour from #4 and #6 SiC crucibles with the forged tongs. Good idea to think about a pouring shank for them.

One more thing about the crucibles: If you can get them, go for the SiC ones. Last winter I fired a graphite type crucible which seems to contained some moisture. There was a lot of cracking noise and some damage. With SiC crucibles there where no such problems - no matter what temperature or moisture. They last quite long.

Last edited by _FL_ on Tue Nov 15, 2011 11:42 am, edited 2 times in total.

Re: My Furnace (1" Hybrid Burner)

Can you expalin the burner mount, it seems like you have added about 8 inch of pipe out of the furnace, where is the 1:12 flare? where is the combustion at??? Did you modify the burner itself in some way?

V/r HT1

V/r HT1

Re: My Furnace (1" Hybrid Burner)

In a furnace you don't need the flare that you see all the Blacksmiths running on their forges. Actually they don't need it either except for when they want to remove the burner from the forge body and use it outside of the furnace or forge.HT1 wrote:Can you expalin the burner mount, it seems like you have added about 8 inch of pipe out of the furnace, where is the 1:12 flare? where is the combustion at??? Did you modify the burner itself in some way?

V/r HT1

The flare is needed on burners working outside of the furnace to create a low pressure area just at the end of the burner tube to cause trubulance in the air/gas stream so the flame will burn. This allows the flame to hang on the flare, I have some nice press formed flares from Zollier that work really well, but a say 3/4 to 1 inch cast iron bushing will do the same job of a piece of pipe that will slide over the burner tube will do the same thing.

They are not needed in the furnace and forges because once the refractory in the burner port gets hot it does the same thing the flare does. Blown burners are not as temperamental as naturally aspirated burners are, and can burn outside of the furnace without a flare if he air to fuel ratio is set correct, but the flare does help hold the flame on the end of the tube.

David and Charlie aka the shop monster

If life seems normal your not going fast enough" Mario Andrette

If life seems normal your not going fast enough" Mario Andrette

Re: My Furnace (1" Hybrid Burner)

Tell that to the A8 SiC that I had blow the side off of while I was preheating hundred dollar crucible ruined, I think it was a case of heating to fast I had reached down and mad a small adjustment to the gas on the burner, which had it at about peak for the amount of air that I was blowing and I believe the burner may of been pointing upwards slightly, the furnace that I was going to use is in a bad spot for burner alignment._FL_ wrote: One more thing about the crucibles: If you can get them, go for the SiC ones. Last winter I fired a graphite type crucible which seems to contained some moisture. There was a lot of cracking noise and some damage. With SiC crucibles there where no such problems - no matter what temperature or moisture. They last quite long.

David and Charlie aka the shop monster

If life seems normal your not going fast enough" Mario Andrette

If life seems normal your not going fast enough" Mario Andrette

Re: My Furnace (1" Hybrid Burner)

that explains everything save the pipe extension, I assume, the extra long pipe is not a problem, though my mind just screams that cannot be true, the gass has to loose volocity in the extra length

Re: My Furnace (1" Hybrid Burner)

I would like to know where you got this SiC crucible. I have only seen spalling like this with Graphite crucibles not a SiC crucible. This was the main reason I went to SiC since in all the years casting I have never had this problem using them, graphite yes.dallen wrote: Tell that to the A8 SiC that I had blow the side off of while I was preheating hundred dollar crucible ruined, I think it was a case of heating to fast I had reached down and mad a small adjustment to the gas on the burner, which had it at about peak for the amount of air that I was blowing and I believe the burner may of been pointing upwards slightly, the furnace that I was going to use is in a bad spot for burner alignment.

I do, however, as good foundry practice, always fire the furnace empty first then after a couple minutes shut it off and then place in the crucible to be slowly warmed up before restarting. I never let a crucible remain in the open air after a pour but return it ASAP to furnace. When I switch from aluminum to brass I remove the al crucible and place it in another furnace that has been running and hot enough to allow that crucible to cool down slowly. In the meantime the main furnace has been heating up the brass crucible before firing it up. I get 100's of pours from my SiC crucibles with never a crack or spall. Yes, they are expensive so a little TLC with reduce your cost per pour a few cent each time. I always store my crucibles off the floor and in an enclosed cabinet. Bob

I used to spend my time to save money but now I'm willing to spend my money to save time.

Re: My Furnace (1" Hybrid Burner)

Mifco, it was a starbrite A8, it had been in the furnace for only about 5 minutes with the burner running on low but as I said the burner may of been pointing up towards the crucible, its been a while since this happened, I think that I had just added a dimmer control to the blower motor for better control of the air, I know that I had just before it happened I had made an adjustment to the gas.

Its one of those things that happen I posted the picture because _FL_ had said that he switched and did not have any problems with the SiC crucibles. What happened to this one has not stopped me from buying from MIfco I just figure that it was one of those things, like used to say in the Army, Shit Happens in this hobby enterprise Shit Happens.

That's a nice collection of Crucibles you have there Bob looks like the one laying on top of the others on the bottom shelf is in need of a long deserved rest.

The one Clay Graphite that I had the crapped out on me was an A4 from BCS, may not of been the Crucibles fault I had been melting C/I in it, it developed cracks in it that the last time I used it I could see the liquid brass thru them so when I poured the melt afterwards I smacked it with a hammer so I couldn't use it again. The Rest of my C/G ones I have gotten from Legend Mining Supply I don't buy the best they offer as I don't expect them to last forever, but the ones I have are holding up very well, even the one that I melted brass in the other day and put borax in as a cover it has a nice glass coating in the bottom and up one side where I poured the melt out.

I use and A10 Silicon Carbide from Mifco now to melt Cast Iron in, that is the only thing that has been melted in it, this last melt I added about a Tablespoon full of granular Fluorspar as a wetting agent to the crucible and I had a lot less slag left in the Crucible that I have had before when I melt. I'm not sure as to just when I should be adding the CaF2 to the pot, what I added this time did not all melt. I have ordered some from Legend that is powdered I believe 10 pounds as quick as it gets here I plan to melt some more C/I and use the powder after the pot has melted but just before I pour.

Its one of those things that happen I posted the picture because _FL_ had said that he switched and did not have any problems with the SiC crucibles. What happened to this one has not stopped me from buying from MIfco I just figure that it was one of those things, like used to say in the Army, Shit Happens in this hobby enterprise Shit Happens.

That's a nice collection of Crucibles you have there Bob looks like the one laying on top of the others on the bottom shelf is in need of a long deserved rest.

The one Clay Graphite that I had the crapped out on me was an A4 from BCS, may not of been the Crucibles fault I had been melting C/I in it, it developed cracks in it that the last time I used it I could see the liquid brass thru them so when I poured the melt afterwards I smacked it with a hammer so I couldn't use it again. The Rest of my C/G ones I have gotten from Legend Mining Supply I don't buy the best they offer as I don't expect them to last forever, but the ones I have are holding up very well, even the one that I melted brass in the other day and put borax in as a cover it has a nice glass coating in the bottom and up one side where I poured the melt out.

I use and A10 Silicon Carbide from Mifco now to melt Cast Iron in, that is the only thing that has been melted in it, this last melt I added about a Tablespoon full of granular Fluorspar as a wetting agent to the crucible and I had a lot less slag left in the Crucible that I have had before when I melt. I'm not sure as to just when I should be adding the CaF2 to the pot, what I added this time did not all melt. I have ordered some from Legend that is powdered I believe 10 pounds as quick as it gets here I plan to melt some more C/I and use the powder after the pot has melted but just before I pour.

David and Charlie aka the shop monster

If life seems normal your not going fast enough" Mario Andrette

If life seems normal your not going fast enough" Mario Andrette