Remelting 356

-

Jeff Clark

- Posts: 85

- Joined: Mon Dec 05, 2011 3:40 pm

- Location: Woods Cross UT

Remelting 356

Is it possible for the quality of 356 to go down after continuous remelt? curious I have some that im sure has seen the rounds.

Pour Naked!

Re: Remelting 356

you should have any problem as most of the alloying elements are not going to burn out, you may mess up the alloy if your adding different metals to the pot, but of course you could also end up with an alloy that would work really good and not know whats in it. If you start having problems with the metal when it comes to machining and finishing it you may want to add a small amount of copper to the melt and let it dissolve to make the alloy harder. or find some pistons to melt they have a high silicon content if I remember correctly, not sure on that.

Hows the covers turning out? any new photos?

Hows the covers turning out? any new photos?

David and Charlie aka the shop monster

If life seems normal your not going fast enough" Mario Andrette

If life seems normal your not going fast enough" Mario Andrette

Re: Remelting 356

you really should not have any problems, as long as you degas and flux properly the metal aught to behave itself like dallen said, copper increases hardness and helps machining, but this is a double edged sword, copper also makes the metal more brittle, I would suggest you choose one source of metal like rims for example and stick to it...

-

Jeff Clark

- Posts: 85

- Joined: Mon Dec 05, 2011 3:40 pm

- Location: Woods Cross UT

Re: Remelting 356

I went ahead and bought some pure 356 casting material price per pound was not bad and to be honest my time is limited and when scraping I feel It's time lost casting its just not worth it to me. I was noticing the stuff was not pouring as well that had been remelted time again it might just be me though. On a side note next week im going to take a old flask and make some changes and try to hang so to say a couple of my parts to cast and see how that works.. more or less just to have some fun I guess.. Ill try and get more pics this weekend Happy Pouring fellas its friday!!

Pour Naked!

Re: Remelting 356

I have checked on 356 ingots near me and it was about $1.50 on the $1.00 compared to scrapping wheels which isnt bad at all as far as I am concerned. My only problem was 800lb pallet minimum and I was not sure on ingot size and if it would fit into my A10. I am now getting up to 600+ lb buys on wheels and getting close to switching over to a #20 so I will probably revisit this soon.

On the reuse. Sure over time the alloy is going to drift some. I try to keep the returns going back in with more virgin stock so the metal turns over in parts before it circulates very much but unless you are selling a part that is spec'd at A356 I wouldnt worry too much. If it is a spec'd part I would use just certified ingot and use the returns in something else.

On the reuse. Sure over time the alloy is going to drift some. I try to keep the returns going back in with more virgin stock so the metal turns over in parts before it circulates very much but unless you are selling a part that is spec'd at A356 I wouldnt worry too much. If it is a spec'd part I would use just certified ingot and use the returns in something else.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Remelting 356

@Heimo, I agree that putting copper into aluminium is a double-edged sword.

About a year ago I chucked a 'goodly handful' of old coins into my aluminium melt. After bringing it back to heat, nothing seemed to have happened to the coins - they had sunk to the bottom of the pot - so I poured in my usual (haphazard) way.

The casting seemed much heavier/denser than normal. Anyway, I happened to drop it and pieces broke-off. A tap with a hammer and it shattered. Yet the bit of it that was big enough to grip in my lathe was so hard I couldn't machine it - the tools just lay on their backs with their feet straight-up.

'Jammer' very kindly did a metallurgical analysis for me and pronounced that the stuff was part-way to being Aluminium Bronze. Obviously, some of the copper of the coins had dissolved into my melt.

I don't think I'll waste any more ali by the indeterminate addition of copper ever again.

Geoff

About a year ago I chucked a 'goodly handful' of old coins into my aluminium melt. After bringing it back to heat, nothing seemed to have happened to the coins - they had sunk to the bottom of the pot - so I poured in my usual (haphazard) way.

The casting seemed much heavier/denser than normal. Anyway, I happened to drop it and pieces broke-off. A tap with a hammer and it shattered. Yet the bit of it that was big enough to grip in my lathe was so hard I couldn't machine it - the tools just lay on their backs with their feet straight-up.

'Jammer' very kindly did a metallurgical analysis for me and pronounced that the stuff was part-way to being Aluminium Bronze. Obviously, some of the copper of the coins had dissolved into my melt.

I don't think I'll waste any more ali by the indeterminate addition of copper ever again.

Geoff

-

Jeff Clark

- Posts: 85

- Joined: Mon Dec 05, 2011 3:40 pm

- Location: Woods Cross UT

Re: Remelting 356

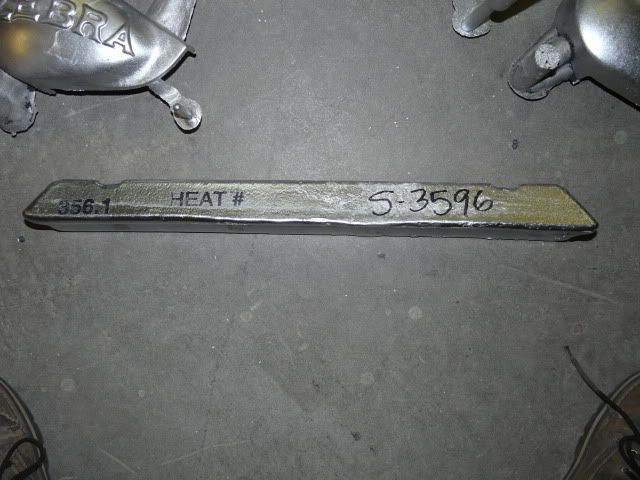

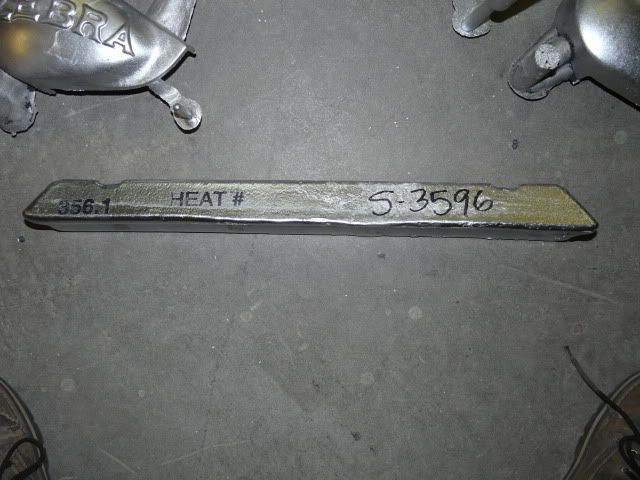

From melting scrap to buying the good stuff I will never go back to scrap, I will remelt the cuts from my parts but scrap goes to the scrap bin, I found I can buy it by the bar here 1.57 a pound last week not worth my time or gas to melt scrap at that price and this stuff pours so nice.

Pour Naked!

Re: Remelting 356

I'm totally jealous. $1.57 a pound. Ingots of my stuff (Everdur) cost so much I have to alloy it myself. I pay + or - $3.35 a pound for #1 scrap copper, and about $3.00 a pound for both silicon and manganese. It's no crap shoot—I know exactly what alloy I am getting—but still, it would be nice to just buy ingots.

Richard

Richard