We should have a safety forum here. I will move this once I get around to making it.

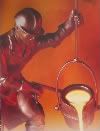

Today on my last mold I had a pisser that was well aimed. This is part of the reason why I like having my molds on the ground but I have been using a bench that is a piece of steel on top of a cinder block so I dont have to reach down so far to set and retrieve molds.

I have quite a number of these because I tend to not follow the rules too well and have several parts I pour regularly that are on matchplates and within 1/2" of the edge of the flask rather than the inch or more that should be there. Well this particular mold isnt one I often have trouble with and it came out right at me rather than the places I expect it with a couple other parts I do. I am pretty quick to pick my foot up and step on the mold to stop it and top off the pouring cup but there was a twist this time.

I got some leggings from my foundry guy last week and figured I would try them out today. As long as I keep them up high they dont bother me but if they creep down (and they want to) they kind of chafe the front of my legs. Well I had just about come to the conclusion that maybe they would be good for brass and iron until this last mold. The metal landed right on the flap over my boot very near where it could have settled into my laces (I know not supposed to have laces but my weak ankles need the support). I was able to ignore it and move on with putting my other foot on the mold and top it off and wait long enough for it to freeze enough I could return the crucible and then knock it off. Wrinkled the leather a little but they are still in good shape and I am convinced, I will be wearing these while pouring from now on.

Pissers

- 4cylndrfury

- Posts: 140

- Joined: Thu Jun 02, 2011 10:09 am

- Location: Cincinnati, Ohio, USA

Re: Pissers

wow, thats crazy! I thought this thread was gonna be about urinals when I saw the thread title lol.

I typically dont use any leg protection aside from a pair of good leather boots with a waterproof tongue, so theres no gap for anything to drop through, and I just make sure to wear denim pants. I have cut up a bunch of my old blue jeans and am making a 3 layer apron from them, and also I have been trying to find a cheap leather trenchcoat at the thrift store to steal the sleeves off of. The idea is to connect the sleeves with some elastic banding so that when youre wearing them, the elastic would cross your back, and a loop of elastic at the other end would go over your middle finger, keeping the sleves in place, but not forcing you to wear a leather coat when you cast lol. If youre like me, you have long welding style gloves you cast with. The sleeves would extend up into the length of the glove, making the chance of metal getting to your skin less likely. The sleves, apron, and gloves offer some pretty good protection. Perhaps if I find that coat, I can use the balance of the leather to create some protection for my legs too!

I typically dont use any leg protection aside from a pair of good leather boots with a waterproof tongue, so theres no gap for anything to drop through, and I just make sure to wear denim pants. I have cut up a bunch of my old blue jeans and am making a 3 layer apron from them, and also I have been trying to find a cheap leather trenchcoat at the thrift store to steal the sleeves off of. The idea is to connect the sleeves with some elastic banding so that when youre wearing them, the elastic would cross your back, and a loop of elastic at the other end would go over your middle finger, keeping the sleves in place, but not forcing you to wear a leather coat when you cast lol. If youre like me, you have long welding style gloves you cast with. The sleeves would extend up into the length of the glove, making the chance of metal getting to your skin less likely. The sleves, apron, and gloves offer some pretty good protection. Perhaps if I find that coat, I can use the balance of the leather to create some protection for my legs too!

"Simplicity is the ultimate sophistication"

-Leonardo Di Vinci

"The future's uncertain and the end is always near...."

-Jim Morrison

-Leonardo Di Vinci

"The future's uncertain and the end is always near...."

-Jim Morrison

Re: Pissers

Yes Harry I agree, we do need a oops or safety forum. I use to wear lace up boots but I have had the odd piece of welding slag dropping into the boot so I now wear elastic sided boots When casting I also wear leather gaiters, leather apron, leather welding gloves and a mesh safety visor

When life gets tough, remember: You were the strongest sperm

Re: Pissers

I dont care for raised pouring surfaces, because of my "appreciation" of the danger of raising molten metal any higher then it has to be. though I will admit, they are all but industry standard, because of ergonomics. I wear leggings, not so much because of "runouts". a technical and PC term for "pissers" . but rather because when I was using steel crucibles, the crucible is VERY close to your leg, and I walked away with blisters on my calf a couple of times. Dont tell my wife, I blamed it on welding

Re: Pissers

I don't think you can get any closed to the sides of a flask then I have with this pour. I have done 40 of these and not had a squirt or aka "pisser". The reason is I clamp and use an aluminum flask. If metal done get to the edge it's in such small amounts that the aluminum flask will quickly freeze off the metal before it can make it to outside. Like has happened in the upper left corner.

With my big wooden flasks I have helper stand by with a hand full of molding sand to stop the start of a squirt just in case by just shoving the sand at the edge of the flask. Only a poorly closed flask were the cope and drag don't line up evenly will cause a major one so just double check after closing. Bob

Bob

Not using safety equipment is an "at your risk" kind of thing. If you get away with it OK but don't cry when it goes bad, if you still can.

With my big wooden flasks I have helper stand by with a hand full of molding sand to stop the start of a squirt just in case by just shoving the sand at the edge of the flask. Only a poorly closed flask were the cope and drag don't line up evenly will cause a major one so just double check after closing.

Not using safety equipment is an "at your risk" kind of thing. If you get away with it OK but don't cry when it goes bad, if you still can.

I used to spend my time to save money but now I'm willing to spend my money to save time.

Re: Pissers

Mike, I always use my mesh face shield and heavy welding gloves too but not so much with the leather jacket when it is hot. I know I should and I hope I never regret it. I also always work in jeans and heavy boots.

HT1, I am a firm believer in keeping the molten metal as close to the floor as I can too. I have switched to using a bench that is 8" high for my molds because that last few inches is the toughest part for me in setting and retrieving molds. Foundry 2.0 will address this by having both the furnaces and molding stations below the level of the pouring floor.

Bob, still working on getting flasks together to have a mostly aluminum assortment to work from. I did begin clamping one part that had been particularly troublesome and have not had a problem since. Honestly I think clamping is easier than weighting and have been considering options on clamps.

HT1, I am a firm believer in keeping the molten metal as close to the floor as I can too. I have switched to using a bench that is 8" high for my molds because that last few inches is the toughest part for me in setting and retrieving molds. Foundry 2.0 will address this by having both the furnaces and molding stations below the level of the pouring floor.

Bob, still working on getting flasks together to have a mostly aluminum assortment to work from. I did begin clamping one part that had been particularly troublesome and have not had a problem since. Honestly I think clamping is easier than weighting and have been considering options on clamps.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Pissers

in the navy we clamped and weighted everything. but there was a rule of thumb. Clamps hold flasks together, weights hold down sand... when you are making LARGE green sand molds, 36 X 36 and larger, a thin cope exploding is a real possibility, weights keep that explosion contained. clamps prevent runouts. of course wood flasks are seldom clamped

(ea story) We had a 48 X48 mold on the deck with (3) 3 inch open risers on it, water vapour boiled out of the risers, shot moltn metal everywhere , and of course the casting was a gassy mess. if it had been a closed mold, there is little doubt it would have bulged or even blown the cope out

(ea story) We had a 48 X48 mold on the deck with (3) 3 inch open risers on it, water vapour boiled out of the risers, shot moltn metal everywhere , and of course the casting was a gassy mess. if it had been a closed mold, there is little doubt it would have bulged or even blown the cope out

Re: Pissers

Yes sand bulging can be an issue but since I use my block molding the sand is backed with wood so as long as the wood blocks are clamped in place no need for weights.

The main issue I see is in not making the clamps too tight and possibly compressing the sand into the void of the mold.

The main issue I see is in not making the clamps too tight and possibly compressing the sand into the void of the mold.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller

Re: Pissers

Harry wrote:The main issue I see is in not making the clamps too tight and possibly compressing the sand into the void of the mold.

That should not be a concern, if you keep the flasks firmly in contact with the matchplate. the only time you SHOULD have to worry about that is if the flasks raise up while ramming. I clamp my flasks to the matchplate while I ram, so no matter how hard I ram, the flask cannot lift

Re: Pissers

I am talking about when pouring after the matchplate is removed.

For molding I use a wooden block above and below the mold that fits inside of the flask and squeezing them too much can collapse the mold. Using the blocks I ram in a shallow layer around the matchplate then add just a little more sand and put it in the squeeze. The blocks stay pressed into the mold when I pour. I end up using close to half the volume of sand for each mold making them lighter to handle and end up processing less sand.

For molding I use a wooden block above and below the mold that fits inside of the flask and squeezing them too much can collapse the mold. Using the blocks I ram in a shallow layer around the matchplate then add just a little more sand and put it in the squeeze. The blocks stay pressed into the mold when I pour. I end up using close to half the volume of sand for each mold making them lighter to handle and end up processing less sand.

I'd rather laugh with the sinners than cry with the saints the sinners are much more fun...

Muller

Muller