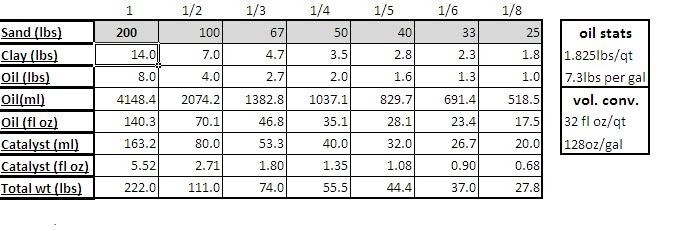

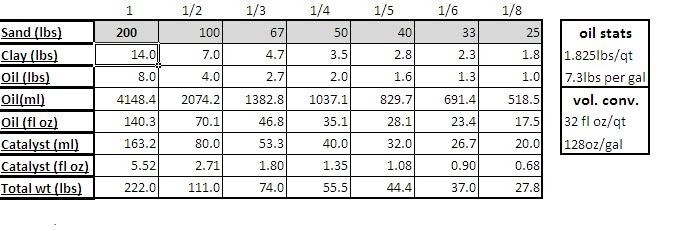

4cylndrfury wrote:The Clay is Specifically

Bentone 34 manufactured by Elementis Specialties. The oil was

Penzoil marine grade 2 stroke oil. Catalyst is just Isopropyl alcohol from the drug store - I have been using the higher concentration - 91% IIRC - which will have less water in it. There has been talk that the water is what actually does the catalyzing, and the alcohol simply helps it disperse in the oil-ridden sand. So its possible that the 73% stuff might actually work better, but Ive done fine using what I have. I have also heard of people using methanol or HEAT engine treatment etc...but because these are alcohols too, I believe its the same thing going on as the isopropyl.

With regards to oil, I initially had found research that indicated that fully synthetic 2 stroke oil may be a good candidate for K-bond sand. Some people made mention of finding "base oils" from oil suppliers - this is oil with absolutely no additives - therefore less chemicals. From what I understand, the additives that are in most oils arent a danger to castings, but to casters - meaning they

MAY represent a health risk when the chemicals burn and are inhaled. In my opinion, there isnt going to be enough exposure on a hobbyist scale to represent a need to acquire these oils. The marine grade 2 stroke has been great for me, I am very happy with the resulting sand.

sorry for not answering sooner, but got sort of busy at work and with driving to new mexico and what not, Thanks for the type of oil that you are using, I thing that harry was using the same type when he was mixing his own.

I have bought powder from both Harry and Retco I also purchased the cat from Retco when I first started mixing my own oil bonded sand, I have used both a 100 grain silica sand and a play box sand that are both bagged and sold by Quikrete thru distrubitors. The Play box sand is on the coarse side but leaves an excellent finish as far as I am concerned. the Silica sand leaves a much finer finish which would be preferred if casting art or parts that were to be plated as the finer finish would leave less polishing before plating.

I have found a supplier in Minniapolis for petrobond 1 and 2 powder plus another one in Lufkin texas. they will both ship by truck but this does drive the cost of the product up by almost if not more than 50 percent. Sand I guess I am lucky in that I have a supplier here local in OKC for the fine grain silica sand from Quickrete. plus I have found a souce in Gainesville Texas that bags sand for United Silica that handles silica cans up to a 225 mesh. that will sell in bags fro 50 to 3000 pounds, just depends on how much you need. the local sand here in Oklahoma also has a high silica content to it and one day I plan on mixing up a small batch of some from the river and see what happens.

Another source for sand that i have located is in kansas and is a river sand that is classified as stove plate sand from Johnson county on eastern kansas if someone was to live in this area they might want to look up Kansas Brass Caster on the old Lionel's Labs site this is the sand that he uses. if asked he may provide information on where this sand can be aquired from. I am sure that people over look a lot of resources in their own backyard's so to speak for sand.

I will try to locate some of the Penn 2 stroke oil, I have been using O'Rielly's 30wt Non Detergent in my sand.

If your interested in building a muller I can supply pictures of mine if you want I really didn't use any set measurements when building it, I kinda followed Steve Chastians book but didn't lock myself into doing every thing that he did. My drive is open and cost a lot less then his did.

I am hoping that the boss will send me to either Minnesota or to lufkin texas if he does I will differently have to stop and pick up a bag of petrobond 2 powder.